Understanding the Cost of Quality in Beverage Manufacturing

Quality is a cornerstone of success in the beverage manufacturing industry. Quality is defined as the measure of excellence, or a state of being free from defects, deficiencies, and significant variations, quality ensures that every bottle, can, or carton that leaves the production line meets the exact taste, safety, and packaging standards set by the manufacturer and expected by consumers.

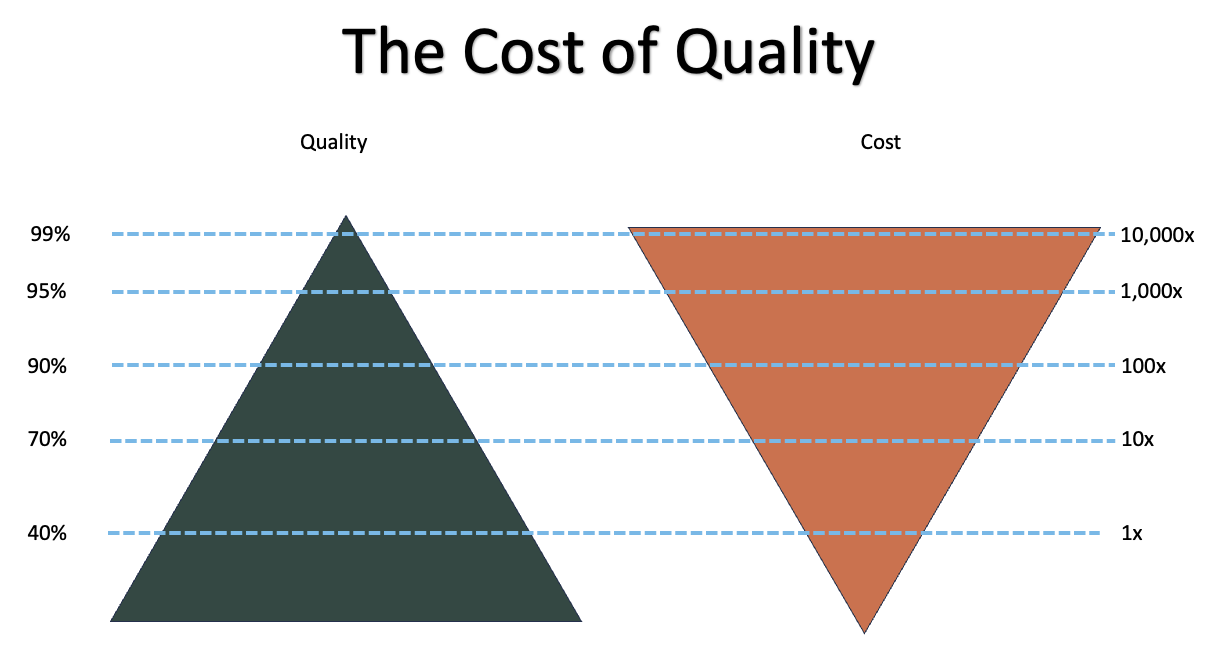

However, achieving and maintaining this high level of quality often comes with a substantial price. The relationship between quality and cost is not linear, but exponential, meaning that as a manufacturer strives to reach higher levels of quality output, the required resources become increasingly intensive.

The Cost of Quality Principle in Beverage Manufacturing

The cost of quality principle is a concept that outlines how the financial investment required to achieve a specific level of quality tends to increase exponentially.

For instance, to produce a beverage with an 80% quality level might cost $100 per batch. Boosting that quality level to 85% might require a $1000 investment, a tenfold increase. Further increasing the quality to 90% could demand as much as $10,000, yet another tenfold increase.

Types of Quality Costs in Beverage Manufacturing

In the context of beverage manufacturing, the costs associated with quality can be broken down into two primary types: Prevention Costs, and Appraisal Costs.

Prevention Costs are the expenses related to activities such as quality planning, employee training, ingredient quality control, and process monitoring to prevent deviations in the taste, safety, and packaging of the beverages.

Appraisal Costs include costs incurred to identify and catch quality issues through activities like beverage tasting, laboratory testing, and packaging inspections.

As we strive to approach a near-perfect or 100% quality output, the cost increases exponentially. Eliminating each successive error, fault, or inconsistency in beverage manufacturing tends to be harder and costlier than the previous one.

The Curve of Diminishing Returns in Beverage Manufacturing

The principle of the cost of quality closely aligns with the economic concept of diminishing returns. As more resources are invested in improving the quality in beverage manufacturing, each additional unit of input results in a smaller increment in output or quality.

To manage this, many beverage manufacturers adopt the concept of “acceptable quality level” or AQL. This is a predefined level of quality that is considered satisfactory. It strikes a balance between the costs of improving quality, such as changes in the production process, employee training, and more detailed inspections, and the costs of poor quality, like customer complaints, returns, and potential brand damage. All manufacturers and brands must set an acceptable quality level. Perfect production is practically impossible. The main question each company to answer is how important is quality to me and what am I willing to pay for it?

The Role of Continuous Improvement in Beverage Manufacturing

While the costs to increase quality can become prohibitively high, it’s essential not to interpret the cost of quality principle as discouraging improvements. Continuous improvement methods like Lean and Six Sigma are increasingly popular in the beverage industry. These methods emphasize small, incremental changes over time to improve quality and reduce waste. Each individual improvement might be small, but over time, they can accumulate to significant enhancements in quality and efficiency without an exponential increase in cost.

Summary

In conclusion, the cost of quality is a critical principle that helps beverage manufacturers understand the financial implications of their quality goals. While striving for high-quality output is crucial, it’s equally important to acknowledge that achieving perfection often comes with a prohibitive cost.

Beverage manufacturers and beverage brands must find their optimal balance between investing in quality improvements and managing costs. This balance allows them to deliver a product that meets both their standards and the end customer’s expectations, without compromising their financial stability.

Mastering the delicate art of balancing quality and cost is not only a necessity but also a competitive advantage. In a market where consumers are increasingly aware and demanding, the manufacturers who can consistently deliver high-quality beverages while effectively managing their costs will stand out and succeed.